PROFESSIONAL PROJECTS

DIGITAL BARCHART

DBC is a digital tool for the visualization and information of the schedule and actual progress of production tasks at Airbus Defence & Space plants.

It is an efficient, iterative and real-time communication system between operators and the engineers who design the manufacturing process.

ACADEMIC PROJECTS

DESIGN AND INTEGRATION OF A MEDEVAC INSTALLATION IN A COMMERCIAL AIRCRAFT

I developed a system integration project for a MEDEVAC installation in an A321neo platform under the supervision of an Airbus advisor.

A complete 'V-model' methodology was applied and modifications in the following aircraft systems were addressed:

- ATA 24: Electrical Power

- ATA 25: Equipment/Furnishing

- ATA 35: Oxygen

In addition, some useful considerations on the installation of this system were provided based on my real experience working in the A330 MRTT FAL.

DRONE-BASED SOLUTION FOR BUSHFIRE DETECTION AND SURVEILLANCE

This one-year group project was developed by 27 students and 5 experienced professionals in response to a 'real customer' request. To make it possible, every member in the team played a different role.

A complete 'V-model' methodology was followed and reviews with the customer were scheduled: PDR, CDR and TRR.

During the process, we faced 'real world' engineering problems which we were able to overcome with intensive teamwork and collaboration.

The design was finally integrated in a DJI F550 drone, flight tested and accepted by the customer.

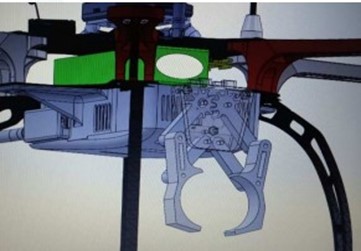

WEAPON RELEASE SYSTEM INTEGRATED IN A DJI F550 DRONE

This project was developed in groups of five students. The purpose was to design the release device and the onboard software to control the launch of the weapon and impact in a given target.

The release device was 3D printed and integrated in a real drone and the whole system was tested in flight, reaching a ten-centimeters accuracy to the target.

BUSINESS PLAN FOR THE INTRODUCTION OF ELECTRIC MACHINES IN A PRODUCTION LINE

This project was developed in groups of five students and aimed to analyze the feasibility of replacing all pneumatic hand machines (screwdrivers, edgers, drilling machines...) with electric ones in an aerospace manufacturing plant.

The study was based on the HTP A320 Production Line and was presented to an Airbus committee.